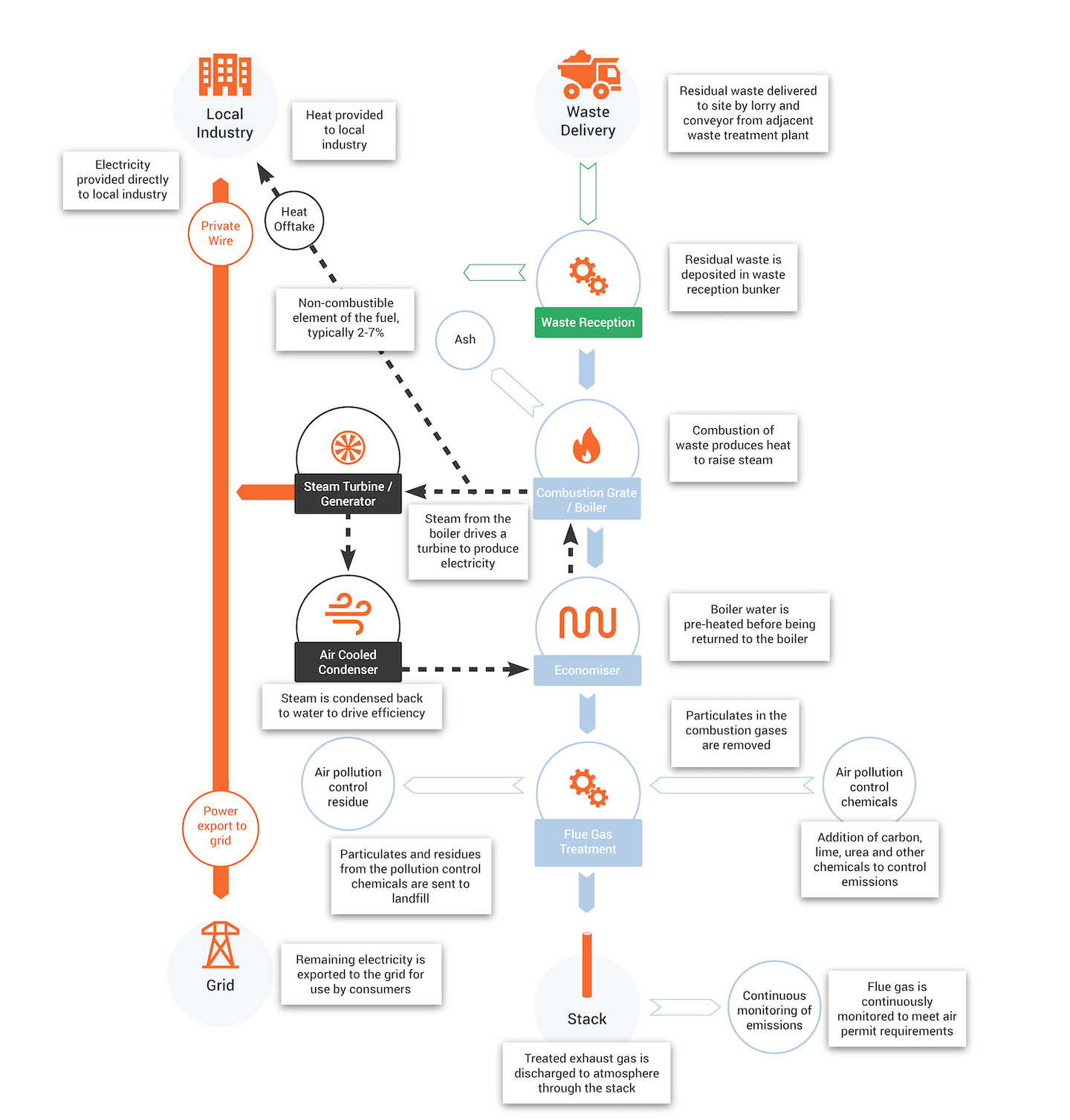

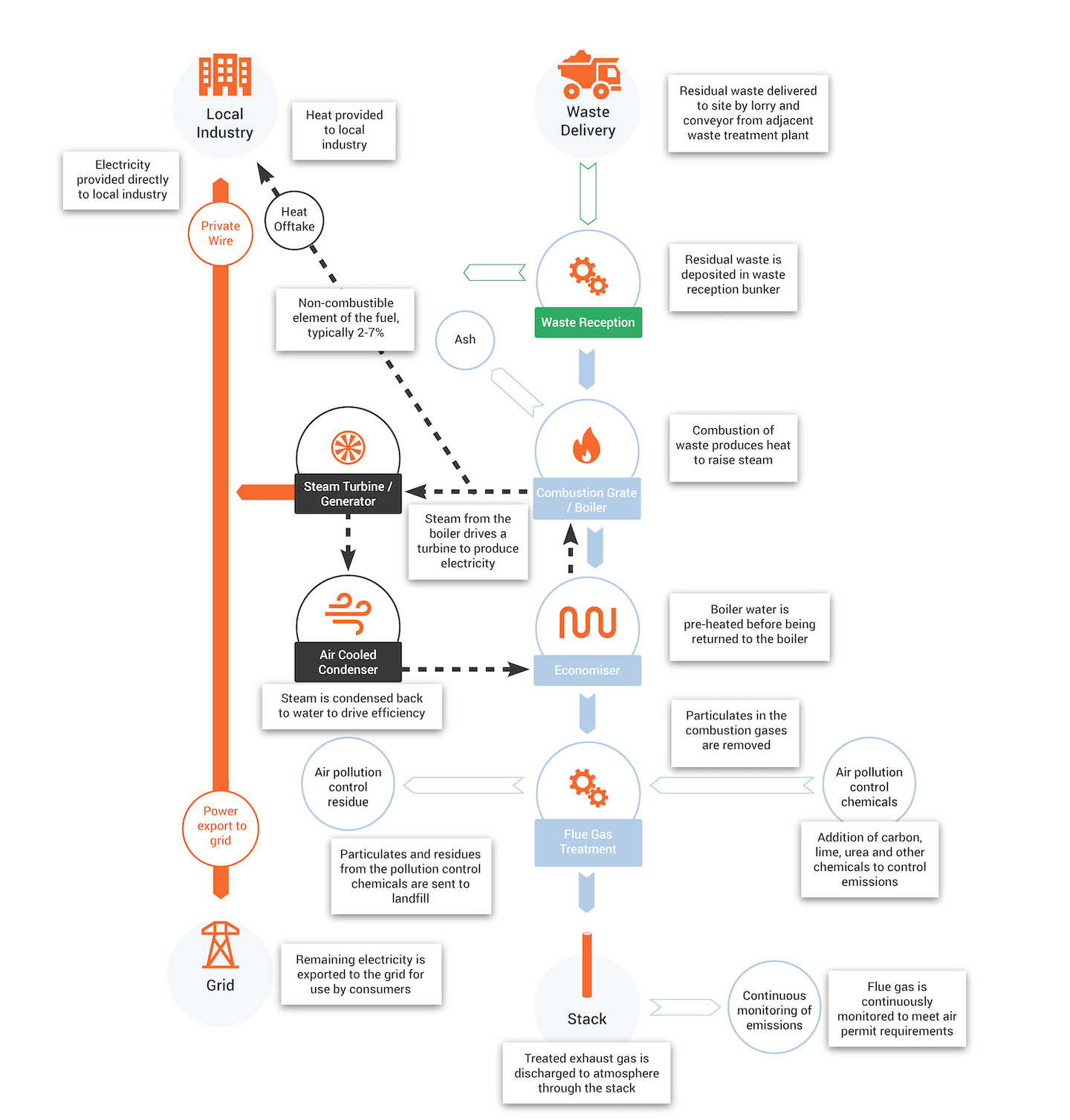

The Northacre facility will utilise conventional moving grate combustion technology. This technology is widely established and proven. It is used in around 90% of the UK’s 48 fully operating energy from waste facilities and in over 400 energy from waste facilities across Europe.

In simplified terms:

- HGVs enter a tipping hall and deposit residual waste in a below ground bunker

- A grab crane picks up the waste and deposits it in a hopper

- The waste moves down the hopper onto a moving / inclined grate

- As it passes along the grate the waste is combusted

- The hot gases from the combustion process pass into the boiler, where they convert tubes containing water into high pressure steam

- The steam drives the turbine and generates the low carbon electricity

- The turbine has a pass-out valve through which low carbon heat can be removed

- The ash from the process drops beneath the grate and is quenched to cool it prior to removal

- The hot gases are then cleaned through a number of processes before being emitted via the stack

- Emissions from the stack are continuously monitored 24 hours / day all year round (24/7/365) to ensure compliance with legislative requirements and our Environmental Permit

Infographic